Technology

It's about making ideas happen.

subsea drilling

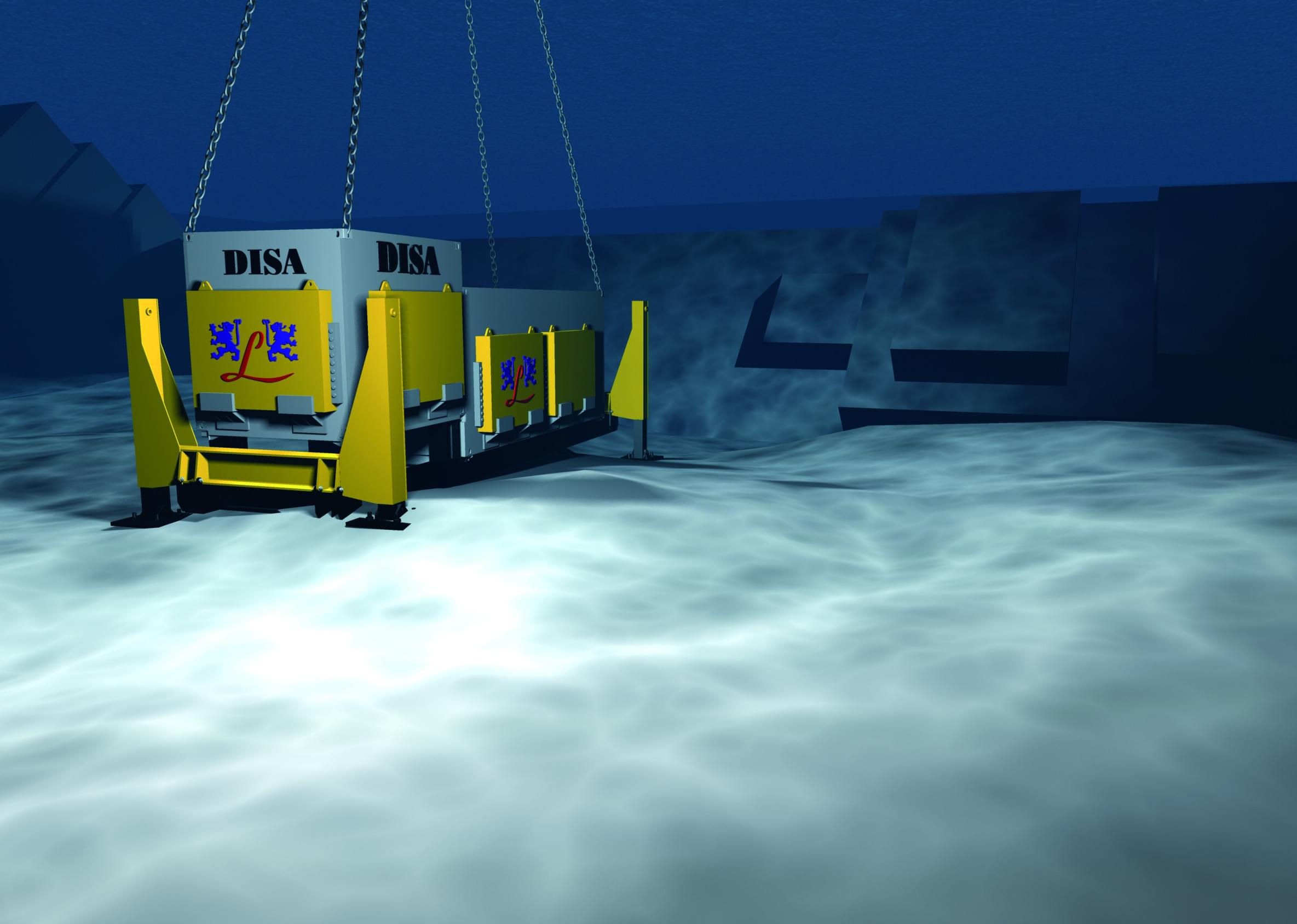

Subsea Drilling has been a worldwide challenge for decades. DISA and her partner Gebr. Van Leeuwen developed in 2006 a specialized, remotely operated underwater drilling device named LEDI Subsea drilling.

The unit was designed for horizontal directional drilling and installation of anchors in the seabed. The services were originally provided through a Joint Venture between DISA International and Gebr. Van Leeuwen BV but since 2010 the JV evolved into LEDI Subsea Drilling BV. The operations today consist off HDD drilling and anchoring services conducted from the seabed by a specialized and completely remotely operated underwater drilling unit.

A detailed track can be provided on request.

SEE PICTURE GALLERY

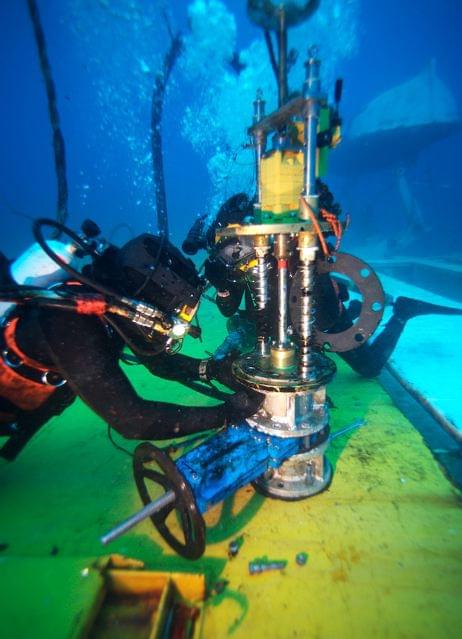

State of the art diving material

As part of DISA’s inhouse expertise and daily subsea operations, DISA owns and operates several containerized IMCA D023 Air/Nitrox surface supplied diving systems. The diving systems can be utilized in conjunction with launch and recovery systems equipped with basket, wet- and dry bell systems, and twin lock decompression chambers. All units are containerized and air conditioned.

Depending on the project and the specific project requirements the SSE system will be installed and commissioned on deck of the floating platform, DP2 or DP3 vessel, or offshore structure.

Remotely operated vehicles

Since 2011 DISA developed an inhouse ROV department to support the subsea operations. DISA owns and operates several ROV’s such as SEAEYE PANTHER XT, SEAEYE COAGAR, SEAEYE LYNX, SEAEYE FALCON, VIDEORAY and DEEPSEA BUNKER OIL RECOVERY ROVSYSTEM.

A large variety of subsea tooling is available for any kind of subsea operations.

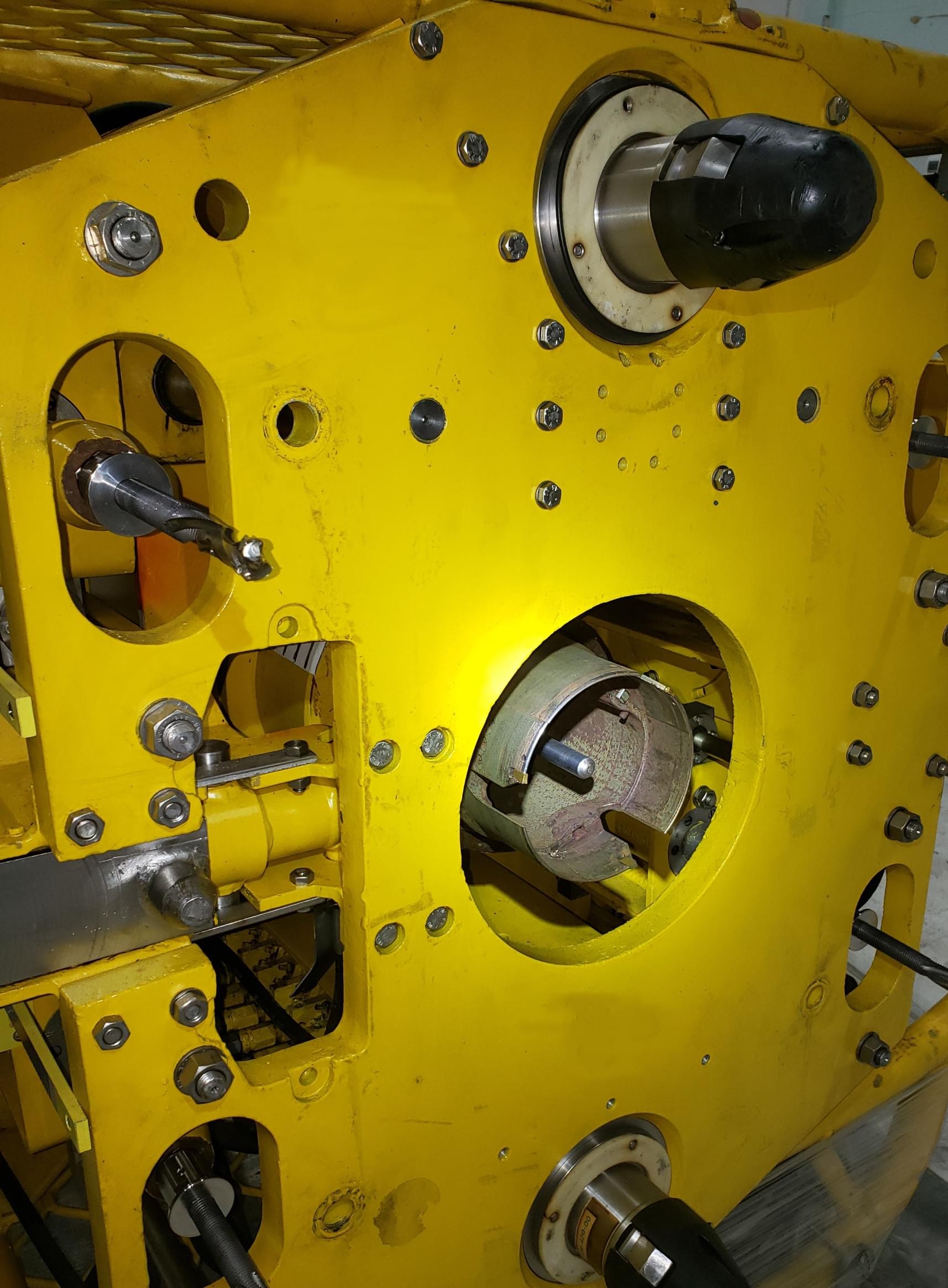

Chainpullers

12 owned chainpullers of 250 ton per unit have been developed and operated since 2008. Each chainpuller can be operated as a single unit or can be interconnected through a specialized control system and perform synchronized lifts or pulls.

The chainpullers are often used in wreck removal operations but known to be used in decommissioning and on shipyards for pull assistance as well.

Hydraulic power pack: 37 kW / SWL: 2500 kN / Maximum value of lateral loading, rectangular to the wheel: 3 degrees / Stroke length: 1,35 m / Self-Weight: 13050 kg / Working pressure: 300 bar / Chain specification: 3".

subsea tooling

A large variety of tooling for diving and ROV operations are available for any kind of subsea operations in our warehouses in Belgium, The Netherlands, Singapore and US. Subsea tooling such as but not limited to: hydraulic operated quick connect and release systems, autogenic and broco cutting systems, all kind of hydraulic tooling such as grinders, cable cutters, jaws of life, concrete crushers, jackhammers, spreaders,…compressed air pressure tooling such as grinders, jackhammers, needle guns,… high pressure water jetting, low pressure water jetting, diamond water cutting tools (for cables and pipelines), ultra-high pressure water jetting, abrasive cutting equipment, welding equipment, patching equipment, Hot tap system out to 6”, CP measurement, MG measurement, accurate depth reference unit, sonars (incl. Blue view), manipulators, submersible pumps, NDT tools.

In addition, all required surface support equipment and other topside equipment is available as well.

underwater concrete

As part of an in-house expertise, DISA has developed over the past years a large variety of high technological underwater concreting equipment. As being an expertized leading service provider for underwater concrete in Belgium, the Netherlands and Germany, DISA is able to execute very complex underwater concrete pouring’s. The complexity varies from, limited accessibility, overcoming large distance whereby floating and subsea transport lines are required, floor specification whereby one or even two inclinations are needed and up to reinforced underwater floors.

DISA applies digital automated measuring systems to accuratly monitor and measure the underwater concrete. DISA conducts these measurments by means of a floating GPS system in combination with altimeters, which relay accurate XYZ information to the control room.

With this system, DISA preloads the construction drawings and plots the trajoctory in order to monitor the underwater concrete in real time via a tablet during the pouring.

The location and height are continiously tracked and analyzed in the system.

One of the additional advantages of this system is that there is a continious collection of data and therefore realtime check on the progress of the underwater concrete.

DISA can post-visualize the pouring with the collected data during the application of the underwater concrete at any given time and on every location thus illustrating the concrete being within tolerances and for further construction analysis.

Our clients recognize and appreciate our vast knowledge and expertise on underwater concreting and along with their needs and requirements we continue to develop in an early stage of their project the safest, most efficient, reliable, time- and cost-effective solution.

Picture Gallery

Underwater Pumping and Injection Techniques

DISA provides a comprehensive range of injection services for concrete repair, leak prevention, soil stabilization, and structural reinforcement. These solutions are particularly valuable when working with underwater concrete, where cracking and settlement during the dewatering of an excavation pit can cause severe leaks, sometimes even carrying sand. Connections to vertical sealing structures, such as sheet piles, diaphragm walls, and CSM walls, are also vulnerable to leakage. Prompt intervention is essential to prevent further damage caused by soil erosion.

With extensive expertise, DISA can professionally resolve virtually any type of underwater leakage. We deliver injection services not only for emergency repairs but also as preventive maintenance, helping you avoid costly issues such as leaks in underwater concrete.

underwater habitats

On several occasions DISA designed and developed habitat units for specific projects. A 30ft habitat unit, which is designed for separation into two individual habitat units of 20ft and 10ft is owned and operated by DISA. All habitats are equipped with lightning, heating, camera’s, breakout box, life support, emergency power and air supply, evac system.

hot taP

A hot tap machine is an enclosed rotary cutting tool which will drill a hole through a tank containing a hydrocarbon or other residue. A hot tap machine is hydraulically driven and has a customized cutting head. The cutter heads are bolted to the drilling bit which in turn is connected to a drive shaft. The advantage of a hot tap is that one can cut access into an otherwise closed oil tank to sample or to install a pumping system for contained hydrocarbon recovery.

See Picture Gallery

Underwater Welding

DISA delevoped since 2005 an extensive program and track record in complex underwater welding, both in the habitat and wet envirmoment. The process involves welding steel together, using specific procedures and systems. The developed procedures are specifically suited to estabilish and create a qualitative, welded joint "in the wet" and "in a habitat" under higher atmospheric pressures. Due to the extremely rapid cooling proces of the weld under water, a critical weld joint need to be developed for it specfic purpose in order to carry the designed load.

DISA holds a range of Procedure Qualification Records under international standards for underwater welding such as; AWS D3.6M, ISO 05613, ISO 15614 and German DVS 1801.

More over than 25 of our divers hold a valid Welder Performance Qualification (WPQ) and are therefore qualified underwater welders. All our welding processes are controlled by our own International Welding Coordinator level B according to NEN-EN-ISO 14731.

Two multi-functional habitats are always ready for deployment to establish critical and specific welding joints under water in dry conditions.

rope access

As from 2012, DISA recognized the need to implement Rope Access services into the current portfolio and add the skills to our in-house expertise package to unburden our clients on their specific requirements. A separate rope access manual was developed and accreditation at the Industrial Rope Access Trade Association (IRATA) was received.

Since rope access has become an additional in-house expertise and service, clients have been served through out all our business lines.

survey and positioning services

Since 2006 DISA invested in a new in-house skill which eventually evolved to a service department which provides and executes all project survey and positioning requirements. A continuous investment since then ensured that the department developed into an expert on a large variety of survey and positioning services to our clients.

The inspection services consist of high definition bathymetric (Multibeam) surveys, Side scan sonar, depth of burial, gradient meter survey, magnetometer survey and real time imaging sonar. In addition, DISA has a variety of surface and subsea positioning equipment such as USBL systems, optic gyro systems both surface and subsea, tug management systems, barge- and vessel mooring positioning and monitoring systems, and anchor handling systems.

pre-lay grapnel run (PLGR)

DISA develops and conducts offshore grapnel services. When specific subsea areas, trackways or trail (paths) are to be cleared of any obstructions, DISA will develop a Taylor made grapnel-line program to clear the area from abandoned subsea cables, ships anchor and chain, steel cables, and debris.

DISA owns and operates a large variety of grapnels such as a detrencher, slinding prong, rennie grapnel, sand grapnel, Gifford, flat fish etc. along with accurate positioning the grapnel operations will be execute according the specifications.

deep sea oil recovery unit

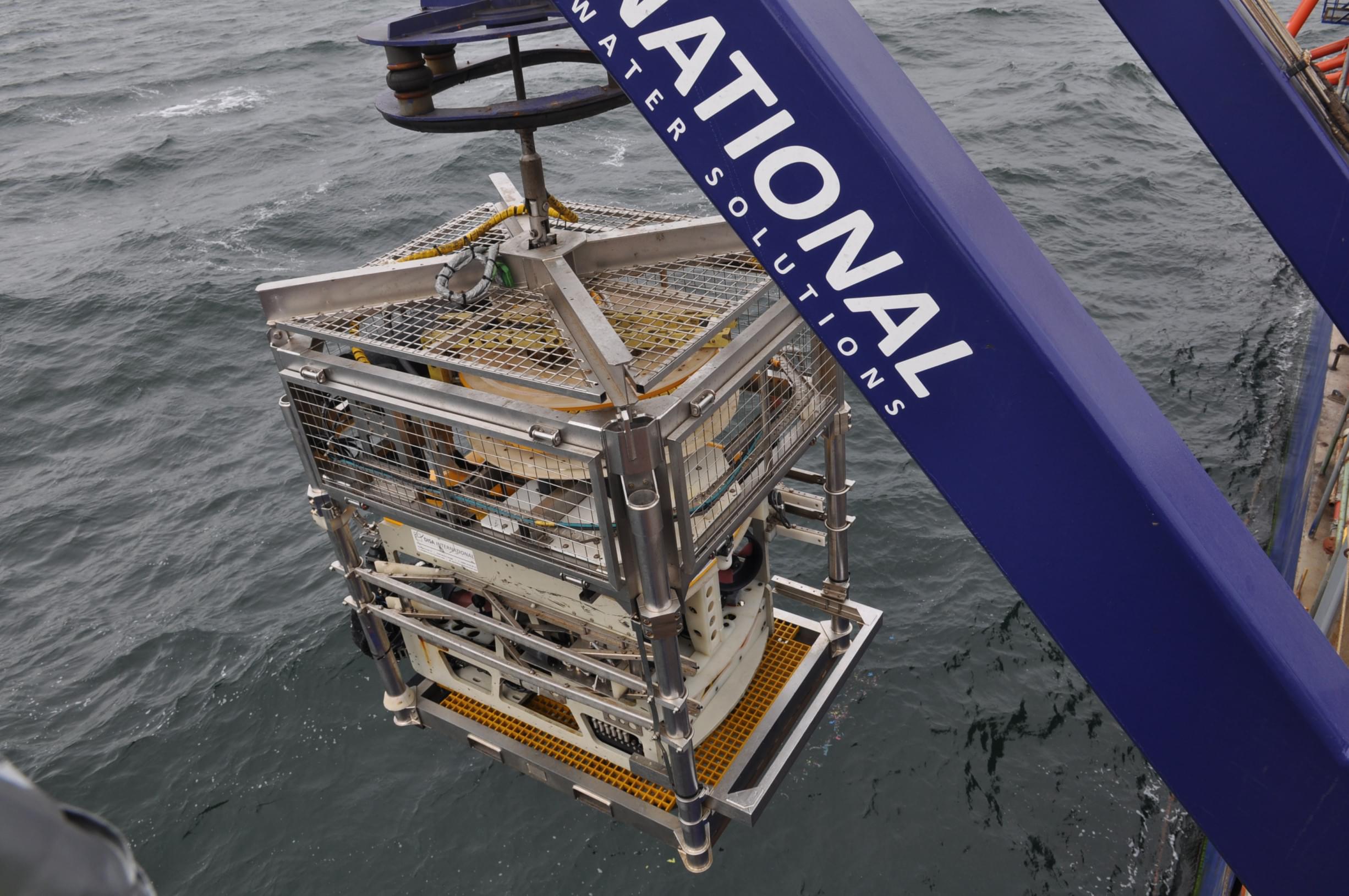

The DSOR is a ROV unit launched and recovered by a LARS or even by the vessels crane and assisted by an ROV designed and developed for recovery of hydrocarbon and other hazardous liquids within subsea structures on depth exceeding air diving and primarily used on sunken vessels. For optimal operation and positioning the unit is fitted with fiber optic gyro, compass, inertia navigation, DVL, video and other measurement systems in addition to cameras and lights.

The DSOR contains necessary electric and hydraulic power for operation to connect and drill through the hull and install an enclosed valve template on to the hull or structure for liquid recovery.

The template has a secondary inlet for a heated/steamed water infusion connection which is sometimes required due to the specification of the liquid and the temperature of the seawater at the working depth. By introducing heat, the viscosity and therefore the poor point is altered making the product more receptible for pumping in order to subtract from the tank or structure.

Further information can be provided on request.

Abrasive cutting

DISA is highly experienced in abrasive water jet cutting techniques in a dry and subsea environment. Our explosion proof abrasive cold cutting system has been developed for operating in hazardous areas such as petrochemical and nuclear areas. The mixture of seawater and absolute environmental neutral abrasives leaves no food print in vulnerable environment. Operators at the surface control station, control and monitor the cutting process with in depth accuracy. The control of the cutting jet can be performed to a distance of 100 metres and contributes to the highest safety of personnel and equipment. DISA provides knowledge and expertise during sub-sea cutting projects and has a wide range of purpose built subsea manipulators for internal and external cutting. DISA abrasive cutting system can cut wall thicknesses up to 90mm in a safe, environmental-friendly cost effective and efficient way.

suction operations

DISA owns and operates several offshore suction pumps for the installation of suction cans, complex skirt foundations and anchor piles. Due to the high capacity, head and endurance of the pump systems large ballasting and de-ballasting operations have been conducted in the past as well. The pump systems can be operated in combination with several different system requirements such as valve control (internal- & external), accurate subsea positioning, real-time orientation and inclination data, pressure and tank read outs.

Generic support equipment

DISA maintain, utilizes and operates a large variety of generic equipment required to support the projects. Equipment such as a large variety of pumps, power generators, hydraulic power packs, RIB's and launch vessels, anti-pollution equipment, rigging equipment, 20” control units, dome- and FLIR camera systems for remote viewing and visual control, communication units such as VHF, base station, and VSAT.