Underwater Innovation - Diverless pile cleaning and breaking

Published on: 22/12/2025

UNDERWATER INNOVATION

Diverless pile cleaning and breaking

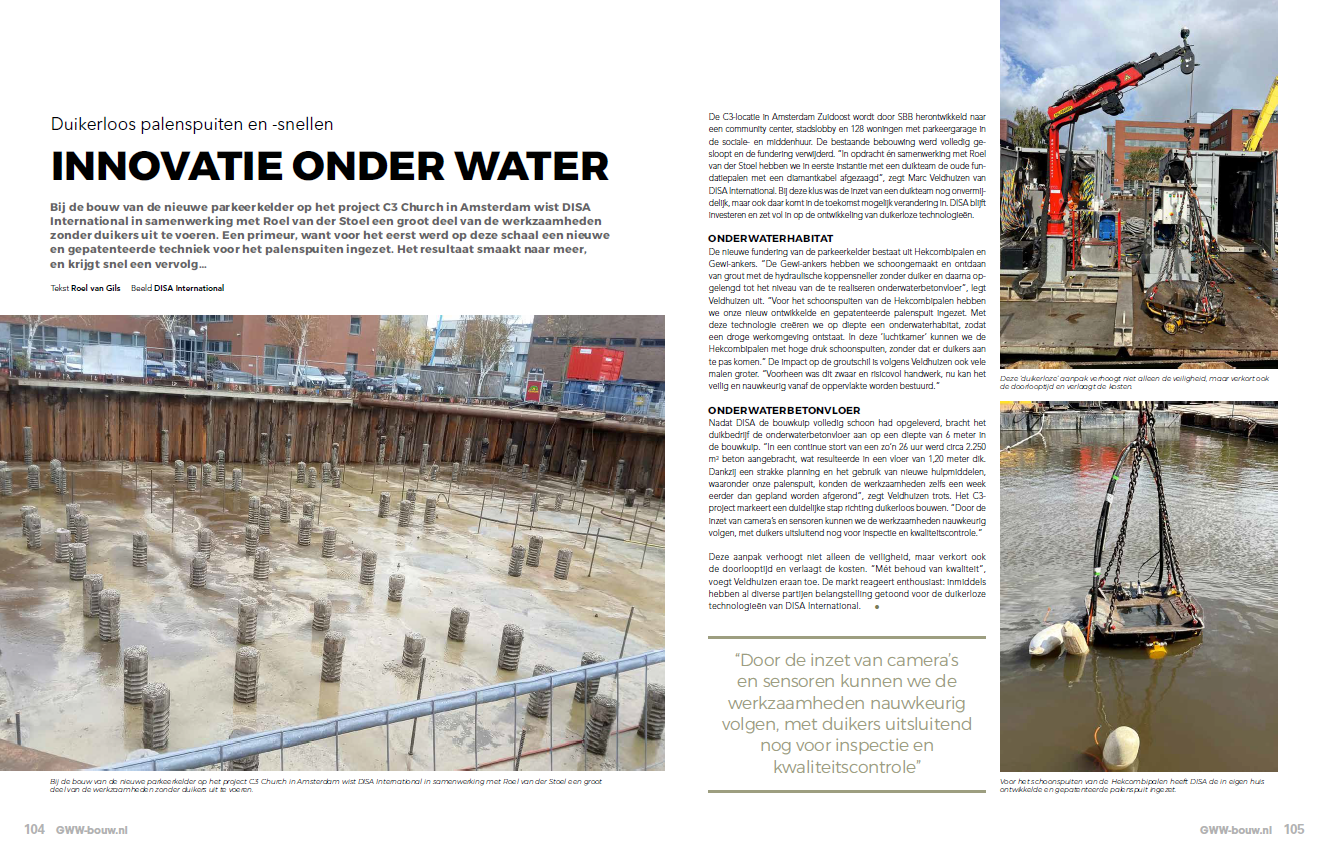

During the construction of the new underground car park at the C3 Church project in Amsterdam, DISA International, in collaboration with Roel van der Stoel, was able to carry out a large part of the work without divers. This was a first, as it was the first time that a new and patented technique for pile cleaning had been used on this scale. The result has whetted our appetite for more, and will soon be followed up...

The C3 site in Amsterdam Zuidoost is being redeveloped by SBB into a community centre, city lobby and 128 social and mid-range rental homes with a car park. The existing buildings were completely demolished and the foundations removed. ‘Commissioned by and in collaboration with Roel van der Stoel, we initially used a diving team to saw off the old foundation piles with a diamond cable,’ says Marc Veldhuizen of DISA International. The use of a diving team was still unavoidable for this job, but that too may change in the future. DISA continues to invest and is fully committed to the development of diverless technologies.

UNDERWATER HABITAT

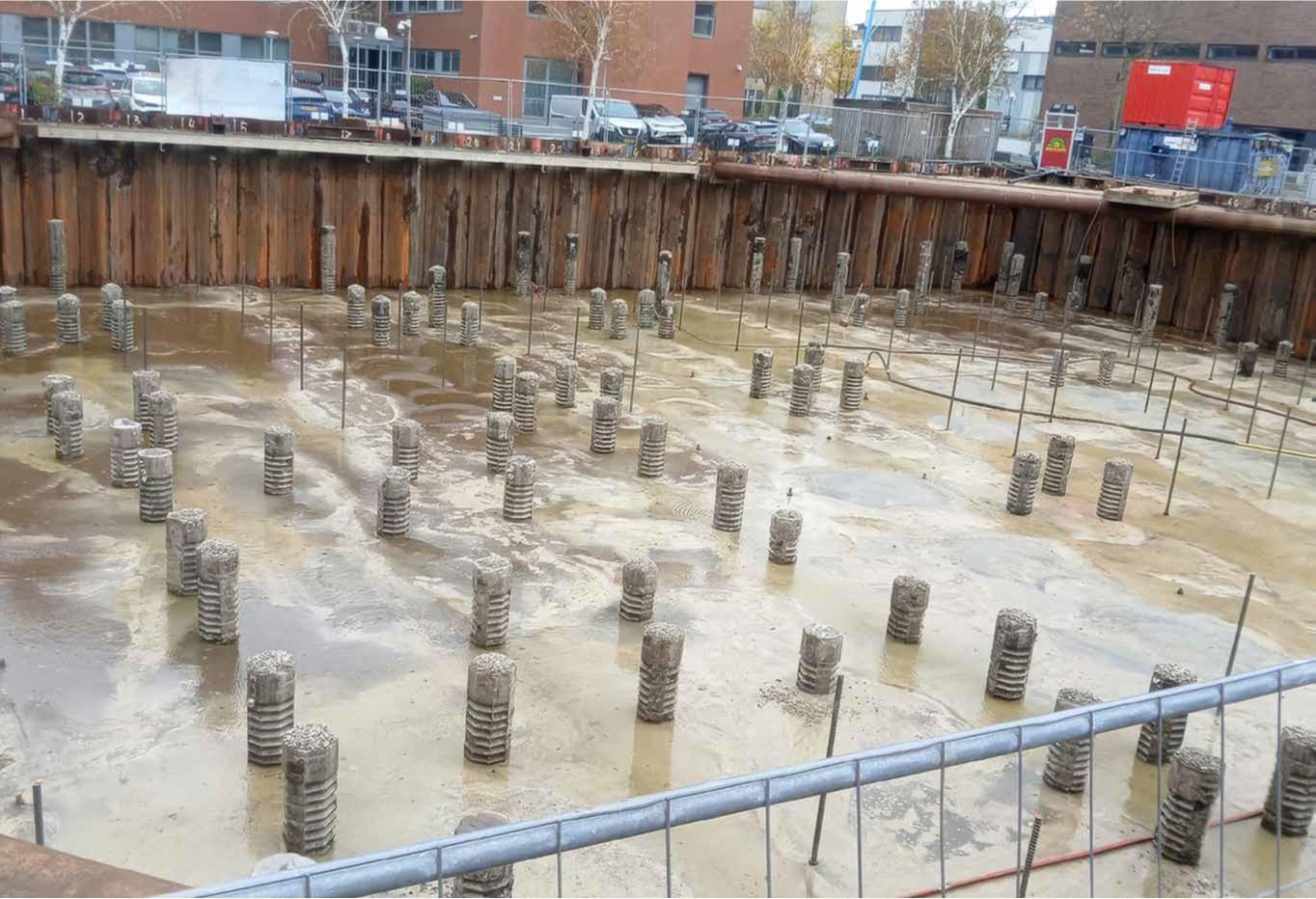

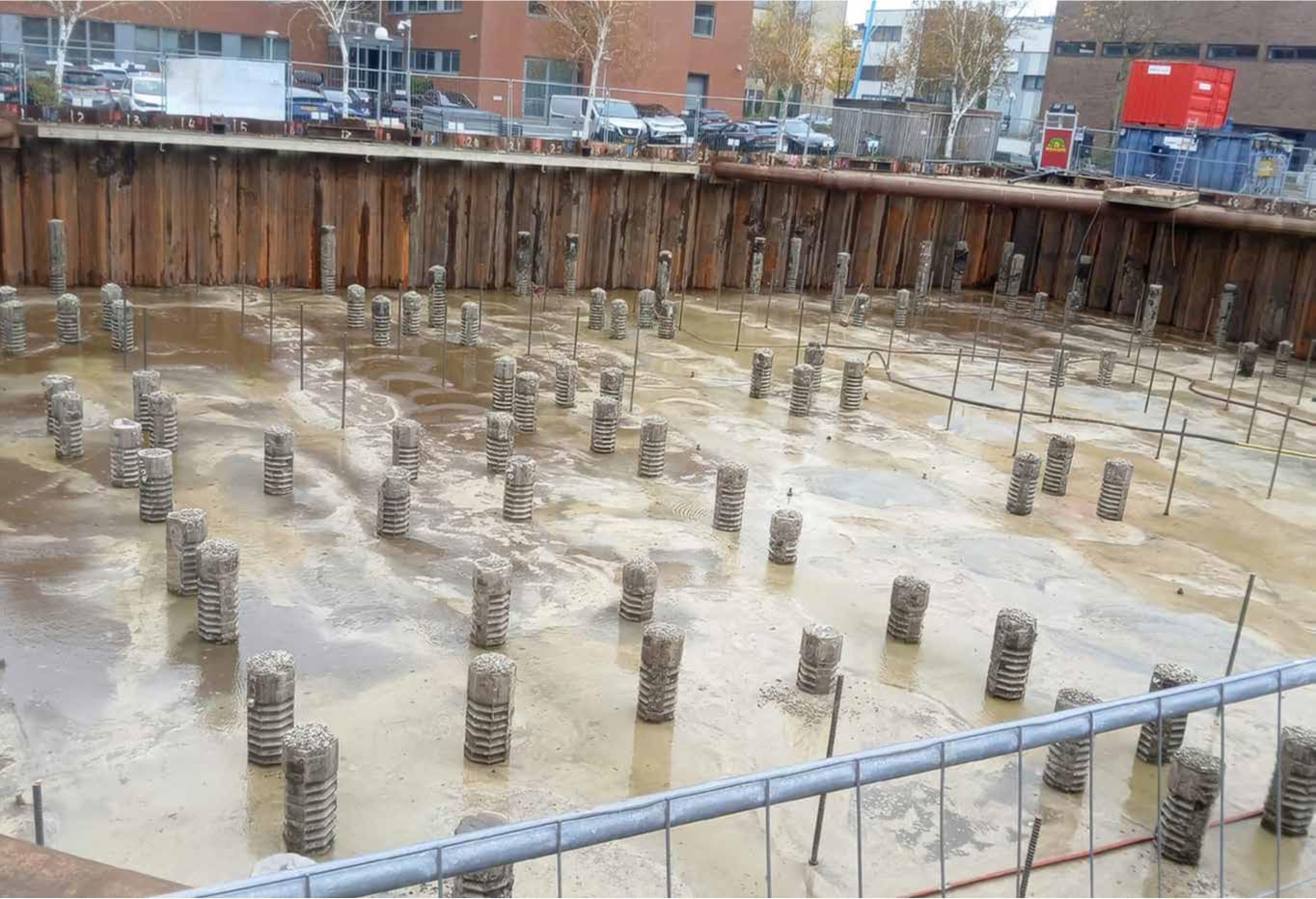

The new foundation of the underground car park consists of Hekcombi piles and Gewi anchors. ‘We cleaned the Gewi anchors and removed the grout using the hydraulic head cutter without a diver, and then extended them to the level of the underwater concrete floor to be constructed,’ explains Veldhuizen. "We used our newly developed and patented pile cleaner to clean the Hek-combipoles. This technology allows us to create an underwater habitat at depth, creating a dry working environment. In this “air chamber”, we can clean the Hek-combi piles with high pressure, without the need for divers.‘ According to Veldhuizen, the impact on the grout shell is also many times greater. ’Previously, this was heavy and risky manual work, but now it can be controlled safely and accurately from the surface."

UNDERWATER CONCRETE FLOOR

After DISA had completely cleaned the construction pit, the diving company installed the underwater concrete floor at a depth of 6 metres in the construction pit. 'In a continuous pour lasting around 26 hours, approximately 2,250 m3 of concrete was laid, resulting in a floor 1.20 metres thick. Thanks to tight planning and the use of new tools, including our pile cleaner, the work was even completed a week ahead of schedule," says Veldhuizen proudly. The C3 project marks a clear step towards diverless construction. ‘The use of cameras and sensors allows us to monitor the work accurately, with divers only being used for inspection and quality control.’

This approach not only increases safety, but also shortens lead times and reduces costs. ‘While maintaining quality,’ adds Veldhuizen. The market has responded enthusiastically: several parties have already shown interest in DISA International's diverless technologies.